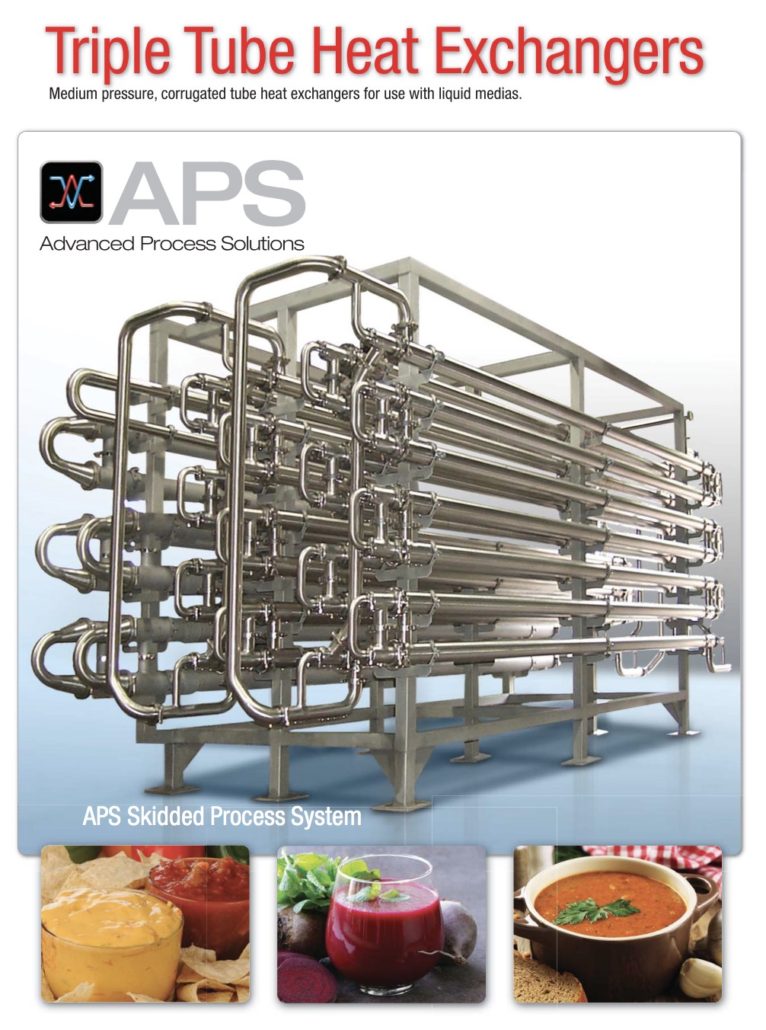

Ultra-Corrugated Triple-Tube Heat Exchangers

Well-suited for thick viscosity products, with or without particulates.

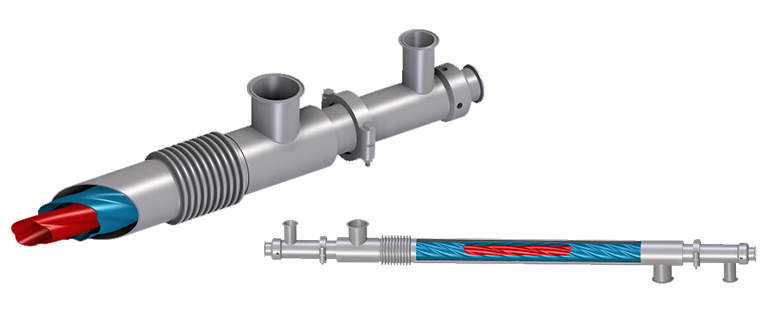

Triple tube heat exchangers have about twice the area of double tube / linear foot. They consist of three concentric tubes — product normally flows in the annular space between the inner and middle tubes. They are well-suited for thick viscosity products, with or without particulates.

Application

Triple tube heat exchangers are ideal for viscous product processing or for direct regeneration heat recovery. Because of the unique nature of the units with media located both on the exterior and interior, and with the product running through a corrugated channel, heat transfer of more viscous products is optimized. Unique dual o-ring design with leak detect to atmosphere separates product from media for safety and security.