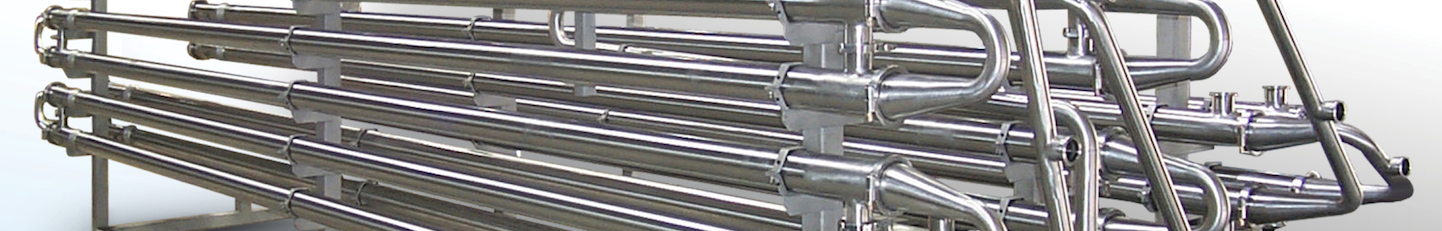

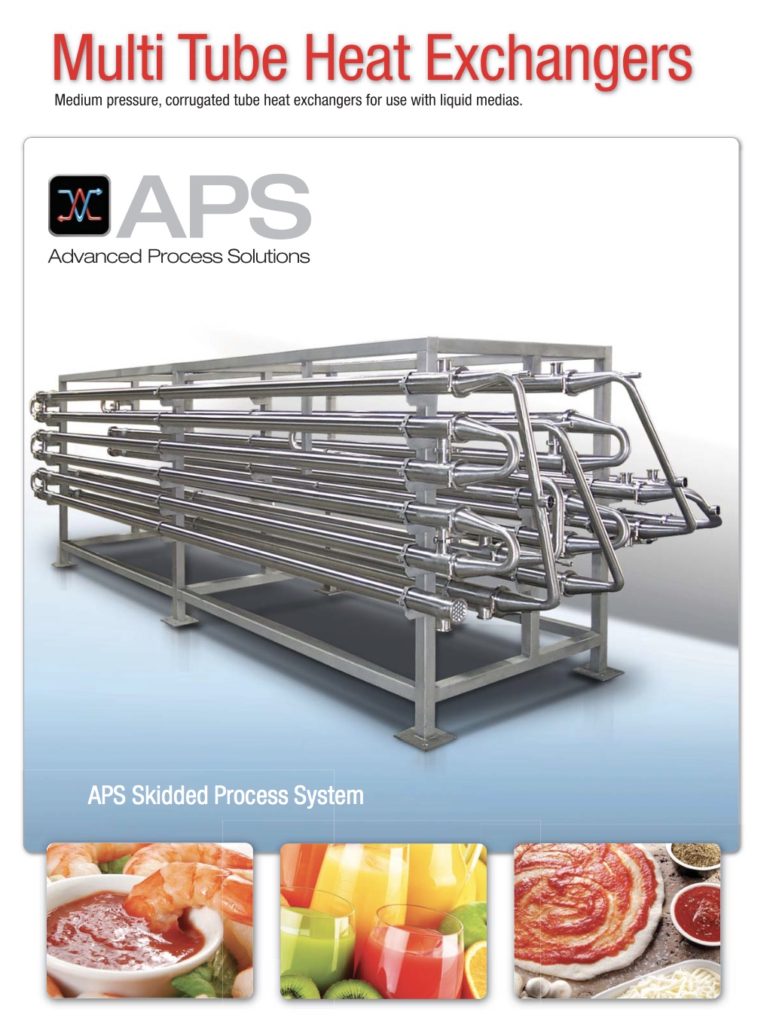

Ultra-Corrugated Multi Tube Heat Exchangers

Medium pressure, corrugated tube heat exchangers for use with liquid medias.

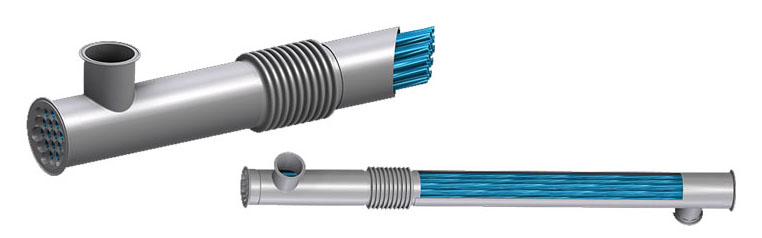

Multi tube heat exchangers consist of three or more parallel tubes inside of a shell. Product flows inside the smaller tubes. This design is ideal for homogenous products with thin to medium viscosities, with or without particulates.

Application

Multi tube heat exchangers are ideal for thin product processing. They can be utilized with pulpy products. Our exclusive and unique “clean-head” design removes all flat surfaces from the tube sheet distribution face for optimum low distribution and CIP cleaning. Multi-tube heat exchangers offer parallel product flow paths for maximum heat transfer area in a small package, with minimum pressure drops. Ideal for juices, nutritional drinks, tea, coffee, milk, and most ready to drink products. Also used on sauces, soups, and concentrates.